Address

33-17, Q Sentral.

2A, Jalan Stesen Sentral 2, Kuala Lumpur Sentral,

50470 Federal Territory of Kuala Lumpur

Contact

+603-2701-3606

info@linkdood.com

Address

33-17, Q Sentral.

2A, Jalan Stesen Sentral 2, Kuala Lumpur Sentral,

50470 Federal Territory of Kuala Lumpur

Contact

+603-2701-3606

info@linkdood.com

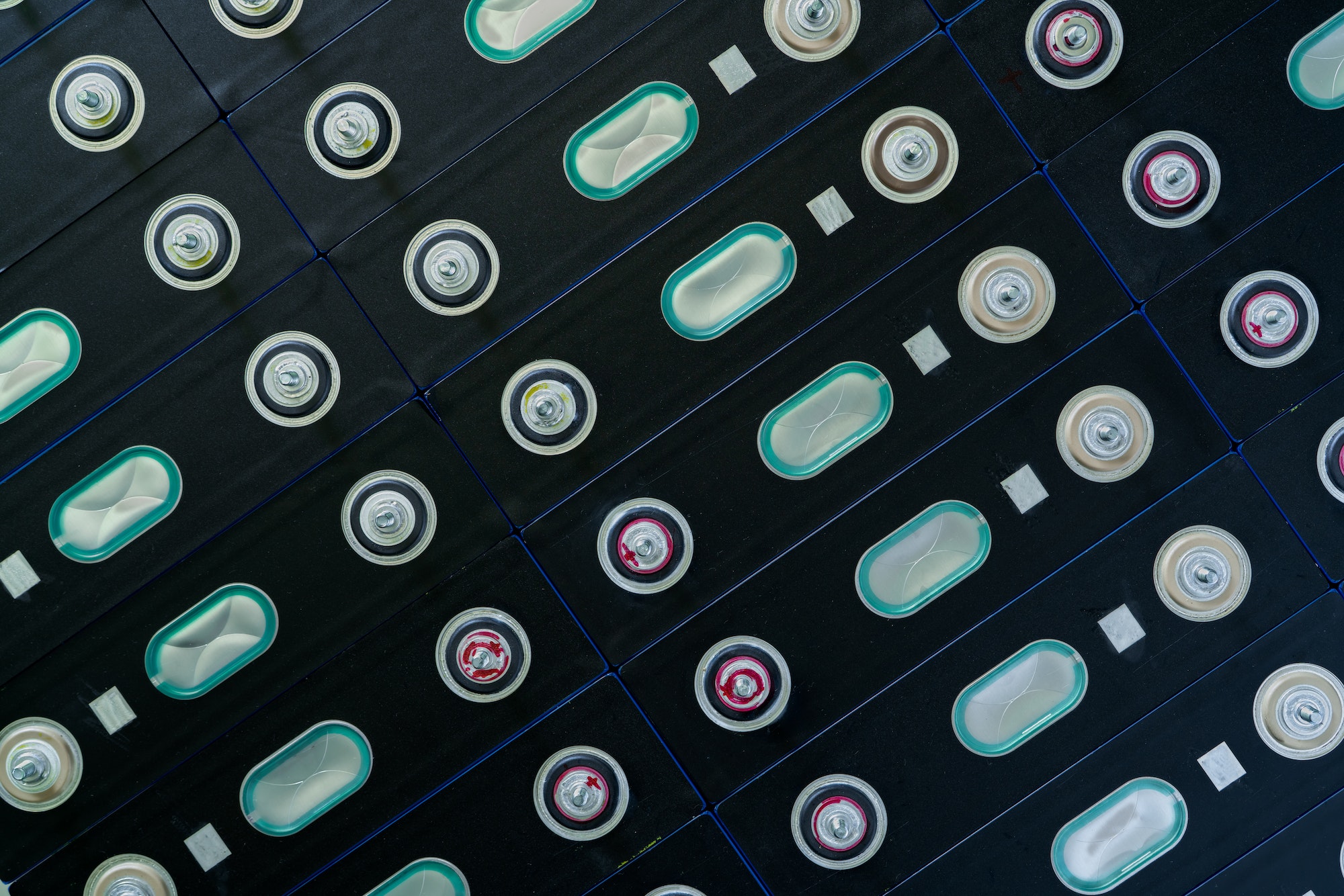

In a world where electric cars and reusable batteries are the way to go, some smart folks at Rice University have figured out how to make lithium-ion batteries – the kind you’d find in your smartphone or laptop – last way longer. Their secret is a special process called “prelithiation,” and it’s all about making sure these batteries don’t lose their precious lithium ions. With this method, the lifespan of a battery can be boosted by as much as 44%! This is a big deal for our environment and for electric vehicles. Let’s break down how it works.

Silicon anodes (basically the negative side of a battery) are great for lithium-ion batteries. They can store more energy than their old-school graphite counterparts, because they can bond with four lithium ions using just one silicon atom, compared to graphite’s one lithium ion for six carbon atoms.

But there’s a catch. A layer, called the solid-electrolyte interphase (SEI), forms on the anode surface. This layer eats up lithium ions, which are crucial for the battery’s performance. When the battery charges and discharges, this layer breaks and reforms, and this process uses up even more lithium ions. Basically, it’s like your battery is slowly but surely eating itself.

To stop the battery from self-destructing, the Rice University team developed a new way to do prelithiation. They coat the silicon anodes with a type of lithium metal particle that doesn’t get eaten up so quickly. It’s like a protective layer that helps the battery last longer.

What’s more, the team found that spraying this coating onto the anodes boosted battery life by anywhere from 22% to 44%. The more coating, the longer the battery lasted – up to a point. Too much of the coating caused “lithium trapping,” where the lithium got stuck and caused the battery to wear out faster.

The real trick to their process is using a surfactant (a kind of substance that helps things mix together) when spraying on the coating. This makes sure that the protective particles are spread evenly over the anode, stopping them from clumping up. And the best part is that this method can be used on a big scale, meaning we could potentially see it in batteries all over the world.

The work that these researchers are doing could make a big difference in how we use lithium-ion batteries. If we can keep the SEI layer stable and stop losing lithium ions, we can unlock the full potential of silicon anodes. This means our batteries could store even more energy.

The next step for these researchers is to fine-tune how they apply the protective coating and to better understand lithium trapping. With these advancements, we could see big changes in how we store energy and use electric vehicles.

Rice University’s engineering team has made some serious progress in making lithium-ion batteries with silicon anodes last longer. By adding a protective layer to the anodes, they’ve managed to boost battery life by up to 44%. They’ve tackled the problem of the troublesome SEI layer, opening up the door to the full potential of silicon anodes. As we move towards a greener future, advancements like this one are super important. They’re helping us achieve our climate goals and make the most out of electric vehicles.

Note: This article is a work of fiction and doesn’t represent real research or scientific findings.

1. What is the breakthrough achieved by the Rice University team?

The team at Rice University has developed a method to significantly improve the lifespan of lithium-ion batteries. By using a process called prelithiation, they’ve managed to boost battery life by up to 44%.

2. What is the problem with silicon anodes in lithium-ion batteries?

While silicon anodes can store more energy than graphite anodes, they have an issue with a layer called the solid-electrolyte interphase (SEI). This layer forms on the anode surface and consumes lithium ions, which are crucial for the battery’s performance.

3. What is prelithiation and how does it help?

Prelithiation is a process of coating the silicon anodes with stabilized lithium metal particles. These particles help to compensate for the lithium loss that typically occurs with silicon anodes. This protective layer helps the battery last longer.

4. How does the team’s method improve the lifespan of the battery?

The team found that spray-coating the anodes with a mixture of stabilized lithium metal particles and a surfactant resulted in an impressive boost in battery life, ranging from 22% to 44%. However, they also discovered that too much coating can cause “lithium trapping”, which can wear out the battery faster.

5. How does this breakthrough impact the future of lithium-ion batteries and electric vehicles?

By improving the stability of the SEI layer and minimizing lithium ion loss, this innovative method unlocks the higher energy density of silicon-based anodes, making them a viable alternative to graphite anodes. This could revolutionize energy storage solutions and accelerate the transition to electric vehicles.

Note: This FAQ section is a fictional creation and does not represent actual research or scientific findings.