With the launch of its new “Physical AI” division, chip designer Arm has made a decisive bet that the next wave of AI growth will not live in chatbots or cloud servers, but in robots, machines, and autonomous systems that move through the physical world.

Arm’s move places it squarely in the middle of a rapidly intensifying race involving tech giants, automakers, and robotics startups — all chasing the same prize: making AI useful beyond text, images, and code.

What Is Arm’s “Physical AI” — and Why It Matters

Arm’s Physical AI division is focused on one goal:

bridging artificial intelligence and physical action.

While most AI today lives in data centers, Physical AI is about systems that can:

- Perceive the real world through sensors

- Make decisions in real time

- Move, manipulate objects, and interact safely with people

This includes robots, autonomous vehicles, drones, industrial machines, and smart devices.

Arm isn’t building robots itself. Instead, it is positioning its chip designs and software platforms as the default foundation for companies that are.

Why Arm Is Uniquely Positioned for This Shift

Unlike companies that sell finished hardware or AI models, Arm operates at the infrastructure level.

Its technology already powers:

- Smartphones

- Embedded systems

- Automotive chips

- Industrial controllers

- Edge devices

As AI moves out of the cloud and into factories, warehouses, cars, and homes, low-power, efficient computing becomes essential — and that’s Arm’s core strength.

Physical AI systems must:

- Run continuously

- React instantly

- Operate with limited power

- Work reliably for years

Traditional data-center AI chips aren’t designed for that environment.

Why the Industry Is Rushing Toward Robotics Now

Arm’s announcement reflects a broader industry shift.

1. AI Models Have Hit a Ceiling in Software-Only Use

Chatbots and generative AI tools are impressive — but their economic value is increasingly saturated. Physical AI offers a new frontier where productivity gains could be much larger.

2. Labor Shortages Are Growing

Manufacturing, logistics, healthcare, and transportation face chronic labor shortages driven by:

- Aging populations

- Physically demanding work

- Skills mismatches

Robotics is no longer just about efficiency — it’s about maintaining output at all.

3. AI Is Finally Good Enough

Advances in perception, planning, and reinforcement learning now allow machines to:

- Navigate unpredictable environments

- Learn from experience

- Adapt to new tasks

The hardware ecosystem is racing to catch up.

What “Physical AI” Actually Includes

Arm’s Physical AI strategy spans multiple domains:

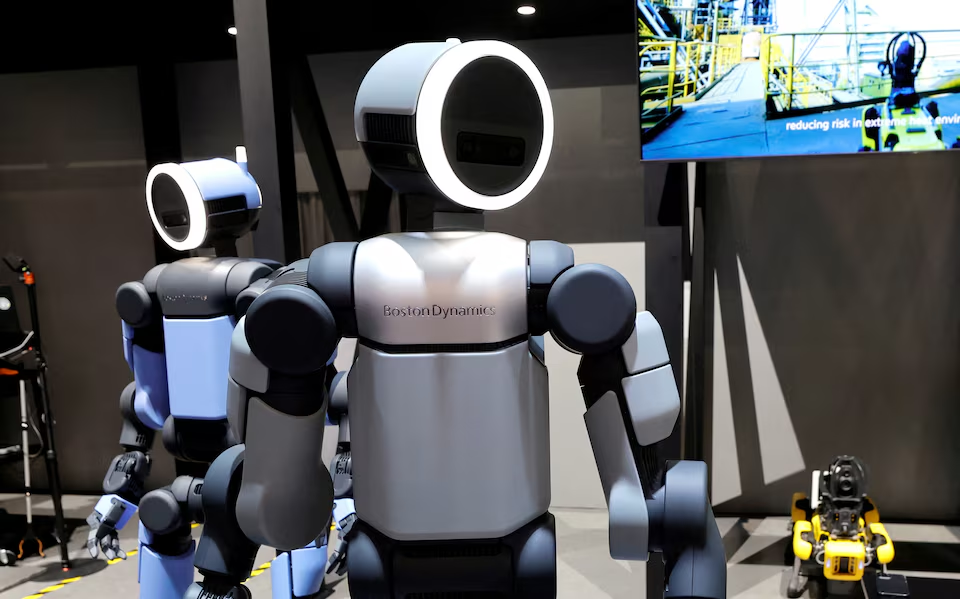

Robotics

Humanoid robots, warehouse robots, industrial arms, and service robots all need efficient on-device AI.

Automotive

Self-driving and driver-assistance systems require real-time perception and decision-making under strict power and safety constraints.

Industrial Automation

Factories increasingly rely on AI-enabled machines that can adapt instead of following rigid scripts.

Edge AI

Processing data locally — rather than in the cloud — reduces latency, cost, and privacy risk.

Arm’s chips are designed for exactly these use cases.

Why This Is a Strategic Move — Not a Side Project

By launching a dedicated division, Arm is signaling that Physical AI is not experimental — it is central to its future growth.

The company aims to:

- Standardize how AI runs on physical devices

- Provide tools for developers building embodied AI

- Capture value as robotics scales globally

If successful, Arm could play a role similar to what it did in smartphones — quietly powering an entire industry.

The Competitive Landscape Is Heating Up

Arm is joining an increasingly crowded field:

- Nvidia is pushing AI systems for robotics and autonomous machines

- Automakers are building in-house AI stacks for vehicles and factories

- Startups are developing custom robotics chips and platforms

What differentiates Arm is neutrality. It doesn’t compete with customers — it enables them.

That makes it attractive to companies that don’t want to rely on a single vertically integrated tech giant.

The Challenges Ahead

Physical AI is far harder than digital AI.

Major obstacles include:

- Reliability in messy real-world environments

- Safety and certification requirements

- Power and heat constraints

- Long development cycles

- High deployment costs

Software improvements alone won’t solve these problems — hardware, sensors, and systems engineering matter just as much.

Why This Matters Beyond Tech

Physical AI could reshape:

- Manufacturing productivity

- Transportation safety

- Elder care and healthcare delivery

- Global supply chains

- Economic competitiveness between nations

Countries that lead in embodied AI may gain advantages similar to those achieved through industrial automation in past decades.

Frequently Asked Questions

What is Physical AI in simple terms?

It’s AI that can sense, decide, and act in the real world — not just generate text or images.

Is Arm building robots now?

No. Arm designs chips and software platforms that others use to build robots and machines.

Why not use cloud AI for robots?

Cloud AI is too slow, power-hungry, and unreliable for real-time physical tasks. Physical AI must run locally.

How soon will this affect consumers?

Industrial and automotive uses will come first. Consumer robots are likely several years away.

Is this another AI hype cycle?

There is hype — but unlike many past cycles, physical AI is driven by real labor shortages and operational needs.

Who benefits most from Arm’s move?

Robotics companies, automakers, and manufacturers that need efficient, flexible AI without building chips from scratch.

The Bottom Line

Arm’s launch of a Physical AI division is a clear signal that AI’s next phase won’t live in the cloud — it will walk, drive, lift, and work alongside humans.

The software revolution made AI intelligent.

The hardware revolution will make it useful.

And as machines begin to understand and move through the real world, companies like Arm won’t just power the future — they’ll quietly define it.

Sources Reuters