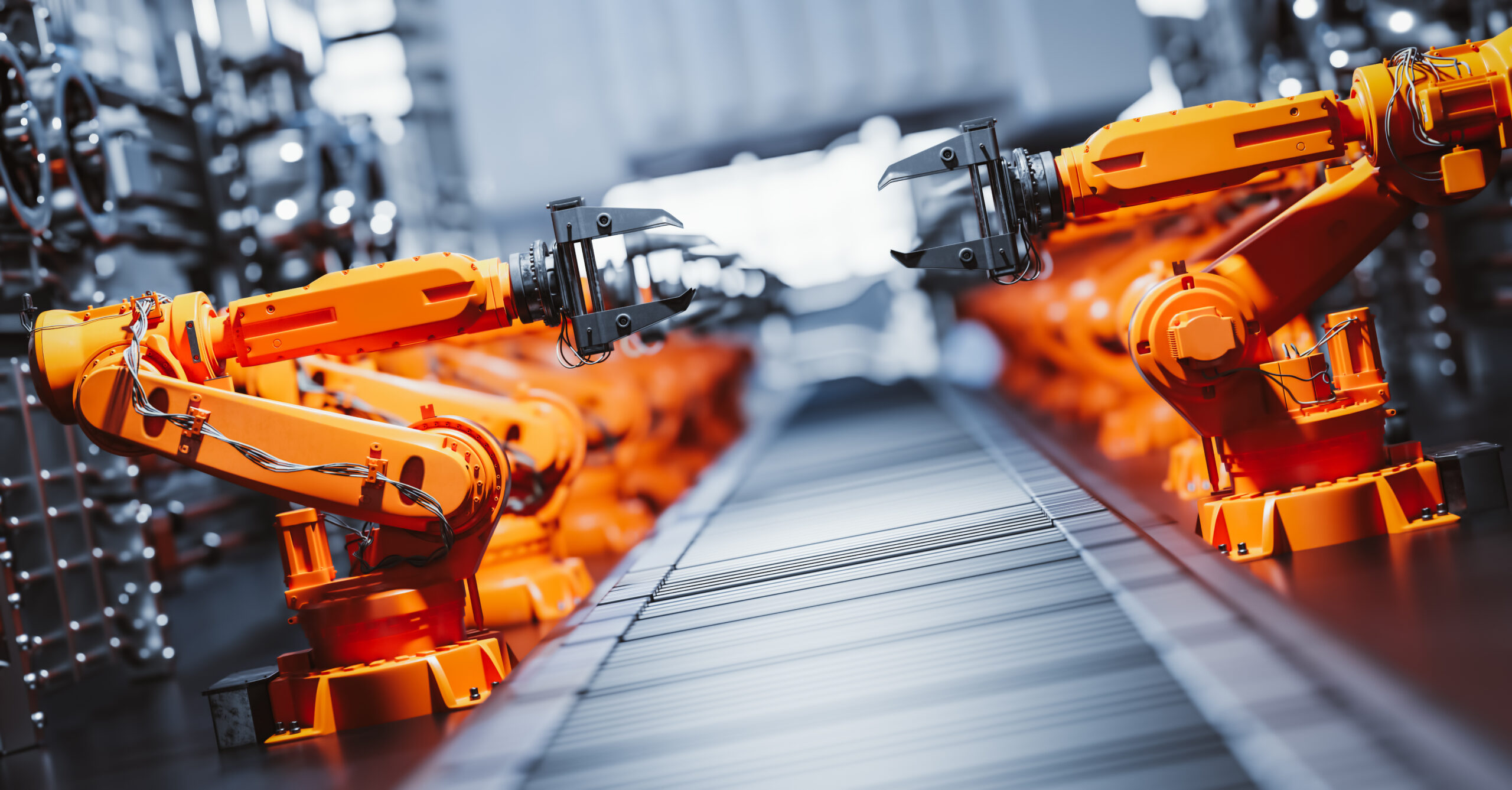

Recently, robots have become super common in factories, aiming to make things faster and better. But sometimes things go wrong, like what happened in South Korea, where a worker died because a robot arm messed up during a late-night check. This sad story has made people think more about how to keep workers safe around robots.

When Humans and Robots Work Together

Now that robots are teaming up with people at work, we’ve got to figure out new ways to stay safe. The accident in South Korea shows us what can go wrong if we’re not careful, especially if robot sensors and safety checks don’t do their job right.

Knowing What Can Go Wrong with Robots at Work

Robots are supposed to make work easier, but they can be dangerous if we don’t handle them well. To stop bad stuff from happening, like what went down in South Gyeongsang province, we need to know the risks and keep a close eye on the machines to make sure they’re working fine.

Really Good Safety Rules are a Must

It’s super important to have top-notch safety rules. That means having clear steps for checking robots, hitting the emergency stop button, and making sure everything’s working as it should. Workers who deal with robots need to know exactly what to do if something seems off. The story from South Korea is a tough lesson on why we always need to pay attention to safety.

Rules and Standards Need to Be Tight

After seeing what can go wrong, people are asking for stricter rules and standards for working with robots. Groups that make these rules have a big job in making sure everyone’s following them by checking in and giving fines if they’re not. Standards from big organizations, like the International Organization for Standardization (ISO), help everyone know how to safely work with robots, and these guidelines need to keep up with all the new tech.

Building Safety into Robots

When making and using robots, thinking about safety can’t be an afterthought. Safety features should include sensors that can tell the difference between things and people, software that always puts people first, and designs that make it easy and safe for people to work with robots.

Cool New Safety Tech

Robot tech is always getting better, and so is safety tech. Now we have stuff like high-tech cameras that can spot people even when it’s tricky, robots that can move in safer, softer ways, and smarter AI that can make better choices when weird stuff happens.

Everyone Needs to Think Safety First

Safety isn’t just about rules and tech. It’s about making safety part of the workplace culture. This means training, getting people to speak up about dangers, and making sure everyone sees safety as their job. Being proactive about safety is the best way to stop accidents with robots.

Learning from the Past

We can learn a lot by looking at what went wrong in the past, like the incident in South Korea. Using these stories in training can help us do better in the future and spread the word on what works best for safety.

Working Together for Safety

To really make workplaces with robots safe, everyone needs to work together. This includes the companies that make the robots, the tech folks, and the rule makers. By sharing what we know and what works, we can make better safety rules that work everywhere.

Wrapping It Up

Robots in factories are super exciting for making stuff better and faster. But as robots become part of the team, we need to make sure that we’re keeping everyone safe. The accidents in South Korea show us what can happen if we don’t. We all need to make sure that as we move towards using more robots, we don’t forget about keeping people safe. By always getting better at what we do, having solid safety rules, and working together, we can make sure that robots help us without putting anyone at risk.

FAQ: Staying Safe with Robots at Work

Why is safety such a big deal when using robots at work?

Safety is huge because robots are powerful and can be unpredictable if something goes wrong. Just like you wouldn’t want to work with broken or unsafe tools, working with robots that aren’t checked for safety can be really risky. That’s why having good safety practices is key to preventing accidents.

What happened in South Korea with the robot?

In South Korea, a worker was killed when a robot arm malfunctioned while he was checking on it at night. This sad event shows how important it is to have solid safety measures and to always be careful when working with or around robots.

What can we do to make sure robots are safe to work with?

There are a few key things:

- Always keep an eye on how robots are performing.

- Have clear steps to follow for regular checks and emergencies.

- Make sure workers know the risks and how to use safety features.

- Update safety rules and training often, so they stay relevant as technology changes.

What kind of safety features do robots have?

Robots can have all sorts of safety features, like sensors that can tell if a human is nearby and stop moving to avoid hurting them. They can also have soft edges or materials that are less likely to cause injury if they touch someone. Plus, there’s emergency stop buttons and AI that can help robots make better decisions in complex situations.

How does having a ‘safety culture’ help?

A safety culture means everyone thinks safety is important and works together to keep things safe. It’s about looking out for each other, speaking up if you see something dangerous, and always being ready to learn how to be safer. It helps prevent accidents because everyone is on the lookout and cares about keeping things safe.

Can learning from past robot accidents actually help?

Absolutely! When we look at what went wrong in past accidents, we can figure out how to stop the same mistakes from happening again. Sharing these stories helps everyone learn and improve, so we can make working with robots safer for everyone.

Why is it important for everyone to work together on robot safety?

When it comes to safety, more heads are better than one. Manufacturers, tech experts, and the people who make the rules need to share what they know and work together to make robots as safe as possible. This way, the safety rules make sense, work well, and cover all the different situations that could happen in real workplaces.

Sources BBC